Most homes don’t fail because of one huge problem; they slowly wear out from dozens of small issues no one ever gets around to fixing. The good news: a lot of those “I’ll get to it later” problems are absolutely doable with basic tools and a free afternoon. This guide walks you through five practical, step‑by‑step repairs that actually solve real annoyances—while saving you money and future headaches.

---

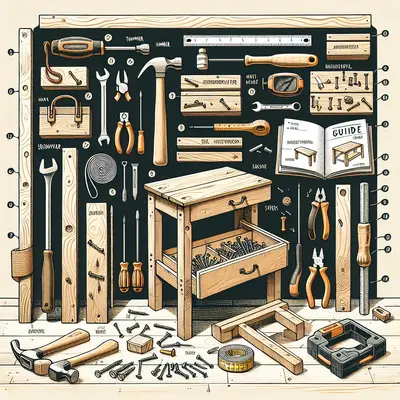

Before You Start: Safety, Tools, and a Smart Setup

Even simple repairs can go wrong if you rush or skip basics. A few minutes of prep makes everything smoother and safer.

First, gather core tools you’ll use for nearly every job: a good screwdriver set (Phillips and flathead), adjustable wrench, tape measure, utility knife, pliers, stud finder, level, and a cordless drill if you have one. Keep painter’s tape, a pencil, and a small flashlight handy—you’ll use them more than you think.

Always turn off power at the breaker for anything electrical, shut off water valves for plumbing work, and wear safety glasses when drilling, cutting, or working overhead. Take a quick photo of anything you’re taking apart (hinges, handle assemblies, faucet parts). Those photos are your “map” when it’s time to put things back together.

Finally, be realistic: if you see signs of structural damage, major electrical issues (burn marks, melted insulation, constantly tripping breakers), or hidden mold, pause and consult a pro. DIY is perfect for small to medium jobs, not for everything.

---

Step‑By‑Step Fix #1: Quiet a Squeaky Interior Door

A squeaky door is annoying—and it’s one of the fastest, most satisfying repairs you can do.

Tools & Materials

- Phillips screwdriver

- Rag or paper towel

- Lubricant (silicone spray, white lithium grease, or petroleum jelly)

Steps

**Confirm the squeak source**

Slowly open and close the door. Listen closely: is the noise from the hinges, latch, or the door rubbing the frame? If it’s the frame, the fix may involve hinge alignment; if it’s clearly the hinge pins, lubrication will usually solve it.

**Support the door (optional but helpful)**

If your door is heavy, slide a thin wedge (like a doorstop or a folded cardboard piece) under it to relieve pressure on the hinges. This makes the next steps easier.

**Loosen one hinge pin at a time**

Starting at the top hinge, slightly open the door and use a screwdriver and gentle tapping (if needed) to lift the hinge pin. You don’t have to remove it completely for a quick fix, but pulling it all the way out lets you clean it better.

**Clean and lubricate the hinge pin**

Wipe the pin with a rag to remove dust and old grime. Apply a thin coat of lubricant to the pin and the inside of the hinge knuckles. Avoid using cooking oils—they gum up over time.

**Reinstall the pin and test**

Slide the pin back in, then open and close the door several times to distribute the lubricant. Repeat the process for the remaining hinges until the squeak is gone. If the door still rubs against the frame, you may need to slightly tighten or loosen hinge screws to realign it.

---

Step‑By‑Step Fix #2: Stop a Running Toilet That Wastes Water

A constantly running toilet isn’t just annoying—it can waste hundreds of gallons of water a day. Most of the time, the fix is inside the tank and doesn’t require special tools.

Tools & Materials

- Adjustable wrench (maybe)

- Replacement flapper or fill valve (if needed)

- Towel or sponge

Steps

**Remove the tank lid and observe**

Gently lift off the lid and place it somewhere safe. Flush the toilet and watch what happens inside. Focus on two main areas: the rubber flapper at the bottom and the water fill level near the top.

**Check the flapper seal**

When the tank refills, the flapper should sit flat and seal tightly. If it looks warped, crumbly, or doesn’t fully cover the opening, it’s probably the culprit. Push it down with your finger—if the running stops temporarily, you’ve found the leak source.

**Adjust the chain**

If the flapper can’t fully close because the chain is too tight, loosen it by moving the clip to give the flapper a bit of slack. The chain should be just long enough that the flapper closes easily, but not so long that it gets jammed under the flapper.

**Inspect the water level**

The water should stop filling about 1 inch below the top of the overflow tube. If it’s overflowing into that tube, adjust the float: - For a float arm: bend the metal arm slightly downward to lower the water level. - For a float cup: turn the adjustment screw or slide the clip on the rod to lower the float.

**Replace worn parts if needed**

If the flapper is brittle or the fill valve never shuts off properly, shut off the water at the valve behind the toilet, flush to empty the tank, and replace the faulty part following the instructions on the new kit. Modern universal flappers and fill valves are designed for DIY installation and usually include diagrams.

---

Step‑By‑Step Fix #3: Patch a Small Hole in Drywall (Without a Mess)

From door knobs to misplaced picture hooks, small drywall holes are almost guaranteed. Patching them cleanly is very doable with a little patience.

Tools & Materials

- Putty knife (2"–4")

- Lightweight spackle or joint compound

- Sanding sponge or fine sandpaper (120–220 grit)

- Damp rag or sponge

- Primer and paint to match your wall

Steps

**Clean and prepare the hole**

For nail or screw holes, scrape away any loose material or flaking paint with the putty knife. If the paper around the hole is torn, trim it back to a firm edge. Wipe the area with a damp rag to remove dust.

**Apply the first layer of spackle**

Scoop a small amount of spackle on your putty knife, press it firmly into the hole, and smooth it across the surface. Feather the edges so the patch blends into the surrounding wall. Don’t leave a big mound; the smoother it is now, the less sanding later.

**Let it dry completely**

Follow the drying time on the product label. Rushing this step leads to cracking or gouging when you sand. For very small holes, drying may only take 30–60 minutes; larger shallow patches might take a few hours.

**Sand and apply a second coat if needed**

Lightly sand the patched area until it’s flush with the wall. If you see low spots or edges, apply a thin second coat of spackle, feathering it slightly wider than the first. Let it dry and sand again.

**Prime and paint**

Spot‑prime the patched area so the paint adheres evenly and the patch doesn’t “flash” (show up as a different sheen). Once dry, paint over with matching wall paint, blending out the edges with a roller or brush. If you’re dealing with a larger hole (bigger than a quarter), you may need a patch kit with a mesh or metal backing—still very DIY‑friendly.

---

Step‑By‑Step Fix #4: Re‑Caulk a Moldy or Cracked Bathtub Joint

Old, cracked, or moldy caulk around tubs and showers lets water sneak behind walls and under floors. Re‑caulking is straightforward and makes the bathroom look cleaner instantly.

Tools & Materials

- Utility knife or caulk removal tool

- Painter’s tape

- Bathroom‑grade silicone or siliconized acrylic caulk (mold/mildew resistant)

- Caulk gun (for standard tubes)

- Rubbing alcohol or bathroom cleaner

- Paper towels or rags

- Small bowl of water (if using silicone)

Steps

**Remove the old caulk completely**

Carefully cut along the edges of the old bead with a utility knife or removal tool. Pull out the loosened strip with your fingers or pliers. Scrape away remaining residue; the new caulk won’t stick properly to dirty or loose material.

**Clean and dry the joint**

Scrub the area with a bathroom cleaner to remove soap scum, mold, and grime. Rinse and then wipe with rubbing alcohol to help the new caulk bond. Let everything dry completely—a few hours if needed. Caulking over moisture is a recipe for early failure.

**Tape the edges for a clean line**

Apply painter’s tape above and below where you want the new bead of caulk to go, leaving a narrow gap (about 1/4" or less) for the actual caulk line. This makes it much easier to get a straight, professional-looking finish.

**Apply the new caulk bead**

Cut the tip of the caulk tube at a 45‑degree angle to match the bead size you want. With steady pressure on the caulk gun, pull the tip along the joint in one smooth pass, filling the gap without big breaks or piles. Work in sections if it’s a long tub.

**Tool and smooth the caulk**

Wet your finger or a caulk‑smoothing tool, then gently press and pull along the bead to smooth it and push it into the joint. Wipe excess on a paper towel as you go. Carefully peel off the painter’s tape while the caulk is still wet. Let it cure for the time specified on the tube (usually 24 hours) before getting it wet.

---

Step‑By‑Step Fix #5: Tighten a Wobbly Handrail or Wall‑Mounted Shelf

A loose handrail or shelf isn’t just annoying—it can be a real safety risk. The goal is to reconnect it solidly to wall studs or anchors that can handle the load.

Tools & Materials

- Philips/flathead screwdriver or drill/driver

- Stud finder

- Level

- Wood screws (long enough to reach studs)

- Appropriate wall anchors (if no stud is available)

- Pencil

Steps

**Inspect where it’s loose**

Gently wiggle the handrail or shelf and note which brackets or mounting points move. Sometimes only one side is weak; other times the whole unit is loose due to stripped screws or failed anchors.

**Remove the rail or shelf (if needed)**

For significant wobble, it’s easier to remove the rail or shelf from its brackets first, then work on the brackets themselves. Keep track of screws and hardware as you remove them.

**Find solid mounting points**

Use a stud finder to locate studs behind the drywall near the existing bracket locations. Mark them lightly with a pencil. Whenever possible, reposition or add brackets so at least some of them are screwed directly into studs.

**Upgrade screws and anchors**

If the old screws were short or only in drywall, replace them with longer wood screws into studs. Where there is no stud, use heavy‑duty wall anchors rated for the expected load (especially for shelves). Drill pilot holes if required by the anchor instructions.

**Reinstall, level, and tighten**

Reattach the rail or shelf, using a level to ensure it’s straight. Tighten all screws firmly, but don’t overtighten to the point of stripping. Test gradually by applying increasing pressure—you should feel solid resistance with little to no movement. If you still notice flexing, add an extra bracket or relocate one to a stud.

---

Conclusion

Tackling small home repairs isn’t about becoming a full‑time handyman; it’s about reclaiming control over your space, saving money, and preventing little issues from turning into big repairs. Fixing a squeaky door, stopping a running toilet, patching a wall, re‑caulking a tub, and securing wobbly fixtures all share the same pattern: observe, prepare, work carefully, and test.

As you work through these kinds of projects, your confidence—and your tool collection—will grow. The next time something in your home starts to rattle, drip, squeak, or wobble, you’ll have a playbook to follow and the mindset to handle it.

---

Sources

- [U.S. Environmental Protection Agency – Fixing Leaks at Home](https://www.epa.gov/watersense/fix-leak-week) - Explains how common household leaks (including toilets) waste water and how simple fixes can help.

- [Family Handyman – How to Fix a Running Toilet](https://www.familyhandyman.com/project/how-to-fix-a-running-toilet) - Step‑by‑step visual guide to common toilet repairs, including flapper and fill valve fixes.

- [The Spruce – How to Patch and Repair Drywall](https://www.thespruce.com/patch-and-repair-drywall-4691897) - Detailed instructions and photos for repairing holes and imperfections in drywall.

- [Bob Vila – How to Caulk a Bathtub](https://www.bobvila.com/articles/how-to-caulk-a-bathtub) - Covers best practices for removing old caulk and applying new, mold‑resistant caulk in bathrooms.

- [Occupational Safety and Health Administration (OSHA) – Hand and Power Tool Safety](https://www.osha.gov/hand-power-tools) - General safety guidelines for using common household tools during DIY projects.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Home Repairs.