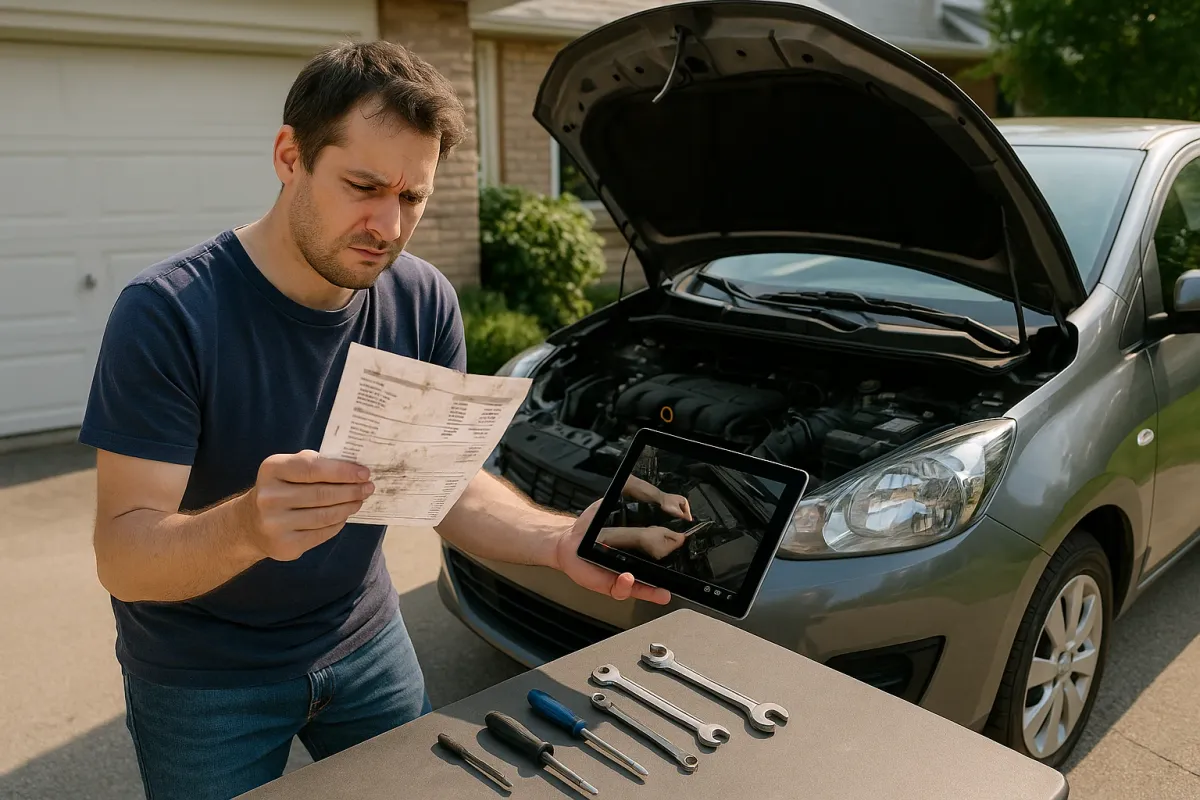

If you’ve ever picked up your car from a shop and thought, “Did they even look at this?” you’re not alone. Viral “Not My Job” photos—where workers do the absolute bare minimum in hilarious ways—are trending again, and the same energy shows up in auto repair all the time: loose clamps, half‑tightened bolts, wrong fluids, and “we topped it off” fixes that solve nothing.

That trending gallery of lazy-job moments isn’t just comedy—it’s a warning. When that attitude creeps into car service, you pay the price in breakdowns, safety risks, and repeat visits. The good news: there are basic checks and repairs you can do yourself that instantly raise the quality bar above the worst “not my job” shop.

Below are five practical, step‑by‑step DIY checks and fixes so your car doesn’t become the next viral “lazy repair” photo.

---

1. Stop the “We Just Topped It Off” Coolant Fix

Shops under time pressure often just add coolant and send you out, without finding the actual leak. That’s like putting a bucket under a ceiling drip forever.

Goal: Confirm your cooling system is sound so you don’t overheat on the highway.

You’ll need:

- Gloves and safety glasses

- Flashlight

- Cardboard or clean driveway

- Coolant (the correct type for your car – check owner’s manual)

Steps:

**Start With a Cold Engine**

Never open a hot radiator cap. Let the car sit at least 2–3 hours.

**Check Coolant Level Properly**

- Look at the translucent overflow tank: it should be between MIN and MAX. - If low, note how low it is; that’s a clue to how big the leak might be.

**Inspect Common Leak Points**

Use a flashlight to check: - Upper and lower radiator hoses (look for swelling, cracks, or dried white/green crust). - Hose clamps (make sure they’re centered and snug, not halfway off the nipple). - Radiator seams and plastic end tanks. - Water pump area (front of engine) for crusty buildup or wet spots.

**Do a “Ground Truth” Test**

- Park over clean cardboard or a clean section of driveway. - Let the engine warm up fully (fans cycling on and off). - After you shut it off, check for drips under the front of the car.

**Tighten or Replace Simple Offenders**

- Loose clamp? Use a screwdriver or nut driver to snug it up—firm, but don’t strip it. - Cracked small hose? Measure length and inner diameter, buy a replacement at a parts store, and swap it: - Loosen clamps, twist the old hose to break the seal, pull off, push the new hose on fully, then re‑clamp.

**Refill and Recheck**

- Add the correct coolant mix to the overflow bottle up to MAX. - Drive normally for a day, then recheck the level and the cardboard. No new drips? You likely fixed it.

If the coolant drops again or you see leaks from the radiator core or under the engine (especially near the firewall), it’s time for a shop—but now you can tell them exactly what you found and avoid a lazy “top‑off” non-repair.

---

2. Undo Sloppy Oil Changes: Filter, Drain Plug, and Leaks

Rushed oil changes are classic “not my job” territory: stripped drain plugs, filters tightened by a gorilla, and oil smeared everywhere so you can’t tell if you have a real leak.

Goal: Make sure your oil system is tight, clean, and correctly serviced.

You’ll need:

- Jack and jack stands or ramps

- Socket set and wrench

- Oil filter wrench

- New drain plug washer (crush washer, if your car uses one)

- Correct oil and filter

- Shop towels and brake cleaner (for cleanup)

Steps:

**Raise and Secure the Car**

- Park on level ground, set the parking brake, chock a rear wheel. - Use a jack and stands or ramps—never rely on a jack alone.

**Inspect Existing Work Before Touching Anything**

- Note oil drips around the drain plug, oil filter, or oil pan. - Look for RTV (silicone) smeared around the plug—sign of a previous bad repair.

**Drain Oil and Check the Drain Plug**

- Remove the plug carefully. Pay attention: - Does it feel gritty or too loose/tight? That hints at stripped threads. - Is the washer missing or crushed flat? Replace it. - If threads on the plug are damaged, replace the plug. - Slightly damaged pan threads can sometimes be saved with a new plug and washer; badly damaged ones need professional repair (helicoil or pan replacement).

**Replace the Oil Filter the Right Way**

- Use an oil filter wrench if needed, but once it breaks loose, spin by hand. - Make sure the old rubber gasket comes off with the filter (a double gasket will leak badly). - Lightly oil the new gasket with clean oil. - Thread on by hand until the gasket contacts the metal surface, then tighten an additional ¾–1 turn by hand. No tools needed for final tightening.

**Refill, Then Clean for Leak Detection**

- Add the correct quantity of oil. - Start the engine briefly, then shut it off and inspect: - Check around the filter and plug for active leaks. - Spray brake cleaner on any oily surfaces and wipe them clean. That way, any new leak is easy to spot.

**Monitor Over the Next Week**

- Check for fresh spots under the car each morning. - Verify oil level on the dipstick after a day or two of driving.

Doing this once lets you correct any shop’s sloppy work and sets a clean baseline so future leaks are obvious, not buried under old grime.

---

3. Fix Misaligned Wipers and Streaky Windshields (Safety 101)

Bad wiper installs feel like peak “not my job”: blades slapped on wrong, parked in the wrong position, or chattering because nobody bothered to clean the glass. When you’re driving in heavy rain, that laziness becomes dangerous.

Goal: Restore clear, quiet wiping so you can actually see in bad weather.

You’ll need:

- New wiper blades (correct size for your car)

- Glass cleaner or 50/50 water–vinegar mix

- Microfiber cloth

- Small flathead screwdriver (for some wiper clips)

Steps:

**Verify Correct Wiper Size and Type**

- Check your owner’s manual or use the parts store lookup for exact lengths. - Make sure left and right blades aren’t swapped if your car uses two different sizes.

**Remove the Old Blades Safely**

- Lift the wiper arm away from the glass carefully—don’t let it snap back. - Press the release tab on the blade connector and slide it off the hook or pin. - If the tab is stubborn, use the flathead screwdriver gently; avoid prying hard on plastic.

**Clean the Windshield Properly**

- Spray glass cleaner or water–vinegar mix on the windshield. - Scrub in overlapping circles, especially where wipers travel. - Wipe dry with a clean microfiber cloth until it squeaks.

**Install New Blades in the Correct Orientation**

- Align the new blade with the arm’s connector type (J-hook, pin, side-lock, etc.). - Slide it in until you hear a solid click—gently tug to confirm it’s locked. - Set the blade against the glass; it should sit flat, not twisted or angled.

**Check Wiper “Park” Position**

- Turn the igniton to accessory, turn the wipers on, then off to let them park. - They should rest just above the base of the windshield, not halfway up or overlapping the trim. - If an arm is crooked, remove it from its splined post (usually under a small cap and nut), reposition it one notch, and retighten the nut.

**Test in Wet Conditions**

- Spray the windshield with cleaner or use a hose. - Run wipers on low and high: - Look for areas they miss (could be wrong size or bent arm). - Listen for chattering (often cured by another glass cleaning, or by lightly wiping the rubber edge with a damp cloth).

Clear, quiet wipers often get ignored at shops because they’re low-margin and “not my job” territory. Done right, they’re one of the biggest safety upgrades you can do in under 20 minutes.

---

4. Correct Half‑Done Brake Jobs: Loose Hardware and Noise

Brakes are where “good enough” should never fly, but rushed jobs happen: missing or loose hardware, dry slide pins, pads that rattle. If you hear clunks or squeals right after a recent brake service, don’t assume “that’s normal.”

Goal: Make sure your brake hardware is assembled correctly and safely.

You’ll need:

- Lug wrench

- Jack and jack stands

- Socket set and ratchet

- Wire brush

- High‑temp brake grease (for slide pins and pad ears)

- Torque wrench (ideal, but not mandatory for basic checks)

Steps:

**Safely Remove a Wheel**

- Park on level ground, set the parking brake, chock the opposite wheel. - Loosen lug nuts slightly with the car on the ground. - Jack up, support with stands, then remove the wheel.

**Inspect Caliper Mounting and Hardware**

- Grab the caliper and try to wiggle it: - Some movement front-to-back (along the slide pins) is normal. - Any loose, clunky feeling top-to-bottom is not. - Check that all caliper bracket bolts are present and snug (compare to the other side if unsure).

**Check Brake Pads for Proper Fit**

- Look through the caliper opening: pads should sit straight, not crooked or loose. - If you can remove the caliper easily (usually two small bolts), slide it off and: - Confirm pads are installed with friction material facing the rotor. - Pads should slide in the bracket with a *slight* resistance, not need hammering or flop loosely.

**Clean and Lube the Slide Pins**

- Remove slide pins (one at a time so you don’t mix them up if they’re different lengths). - Wipe off old crusty grease and rust with a rag or wire brush. - Apply a thin coat of high‑temp brake grease and reinstall. - Pins should move freely in and out by hand.

**Replace or Adjust Anti‑Rattle Clips**

- Pads often sit in small stainless clips; if they’re missing, bent, or rusted solid, replace them. - Clip them in fully so they sit flat in the bracket before installing pads.

**Reassemble and Torque**

- Reinstall caliper and bracket bolts; tighten them firmly (check your vehicle’s torque spec if possible). - Reinstall the wheel and tighten lugs in a star pattern, snugging them evenly.

**Test Carefully**

- Before driving, pump the brake pedal a few times to seat the pads. - Do a low-speed test in a safe area: listen for clunks, grinding, or strong pulls to one side.

If anything looks deeply wrong—missing bolts, cracked rotors, pads nearly falling out—don’t drive it. At that point, the fix is beyond casual DIY and needs a competent shop (emphasis on competent).

---

5. Fix Misaligned Headlights Shops Often Ignore

A lot of shops will happily “install” new headlights but skip alignment completely. The result: you can’t see far enough at night, or you’re that person blinding everyone else in traffic.

Goal: Aim your headlights correctly so you get maximum visibility without dazzling oncoming drivers.

You’ll need:

- Flat, level driveway or parking lot facing a vertical wall or garage door

- Measuring tape

- Masking tape

- Phillips or flathead screwdriver (or socket) for adjusters

Steps:

**Prepare the Car and Surface**

- Check tire pressures and remove heavy cargo from the trunk. - Park on level ground, 10–25 feet from a flat wall, nose pointing at it. - Make sure fuel tank is around half full.

**Find the Headlight Center Height**

- Measure from the ground up to the center of each headlight lens. - On the wall, use masking tape to mark that height directly in front of each headlight. - Then place a second tape line about 2 inches *below* that line (for low‑beam vertical aim).

**Turn On Low Beams Only**

- Turn off fog lights and high beams. - Sit in the driver’s seat while lights are on (or have someone of similar weight sit there).

**Adjust Vertical Aim**

- Pop the hood and locate the vertical adjuster for each headlight (check your manual). - Aim for the top of the main cutoff beam pattern to rest at or just below that lower tape line. - As you adjust, watch the hotspot: it should not be significantly above your marks.

**Adjust Horizontal Aim (If Adjustable)**

- Some cars only have vertical adjustment; if you have a horizontal screw, use it. - The most intense part of the beam should fall slightly to the right of the vertical centerline (for right‑hand‑drive markets like the U.S.) so you don’t blind oncoming traffic.

**Verify on a Dark Road**

- Do a short test drive at night: - You should clearly see lane markings and road edges without constantly getting flashed by oncoming drivers. - If people are still flashing you, lower them a touch more.

Correctly aimed lights make night driving less stressful and are often better than a bare‑minimum “bulb swap” from a quick-service shop.

---

Conclusion

Those viral “Not My Job” photos are funny until the same attitude meets your brakes, cooling system, or headlights. In the real world, a half‑done repair isn’t just lazy—it can be unsafe and expensive later.

By checking for coolant leaks instead of endless top‑offs, re‑doing sloppy oil changes, fixing wipers, inspecting brake hardware, and aligning headlights yourself, you turn your driveway into a quality‑control station. You don’t need a full shop—just basic tools, a bit of time, and the willingness to say, “Actually, that is my job.”

If you’ve found a shockingly lazy repair on your own car—a loose bolt, missing part, or something that made you say “no words”—it’s exactly the kind of story worth sharing. It might be entertaining, but it might also save someone else from the same headache.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Auto Repair.